Arc welding and laser welding are two prominent welding methods used in many industries for joining metal components. While both techniques create strong, durable welds, they vary significantly in heat source, equipment, speed, and power, all of which impact performance.

What Is Arc Welding?

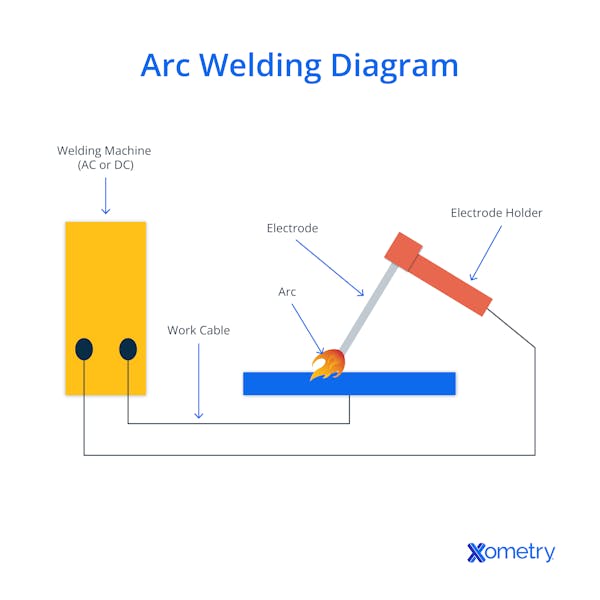

Arc welding joins metals using an electric arc between an electrode and the workpiece, forming a molten weld pool. For a detailed explanation of how the process works, see the section below. The heat generated by the arc melts the metals, forming a weld pool of material from both pieces. When the pool solidifies, it creates a strong joint.

There are several types of arc welding processes, including Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), Flux-Cored Arc Welding (FCAW), and Gas Tungsten Arc Welding (GTAW).

For more information, see our guide on Arc Welding.

How Important Is Arc Welding in Manufacturing?

Arc welding holds immense importance in the manufacturing industry as one of the most common welding processes. Its significance lies in its versatility, reliability, and functionality on a wide range of materials and thicknesses. Arc welding can be applied to different metals, including steel, stainless steel, aluminum, and copper, allowing manufacturers to cater to diverse needs. It produces strong and durable welds, ensuring the structural integrity and longevity of manufactured products. Arc welding is also more affordable than other options since the equipment and consumables required are relatively inexpensive.

What Is Arc Welding Used For?

Arc welding is used to join metal components in industries such as construction, oil and gas, and automotive manufacturing. Some common applications of arc welding include:

- Repairing broken or damaged metal components, machinery, and industrial equipment.

- Joining metal components in automotive manufacturing, such as chassis frames and exhaust systems, typically using MIG (GMAW) welding. While arc welding methods can be used for body panels, resistance spot welding is more common for thin sheet metal.

- Joining steel plates, sections, and other structural components in shipbuilding operations.

- Fabrication of metal structures such as gates, fences, railings, and frames for buildings and infrastructure projects.

- Artistic and sculptural creations using metal materials.

How Does Arc Welding Work?

Arc welding relies on the phenomenon of arc discharge, which occurs when an electric current passes through a gas, creating a bright light and intense heat. When the voltage between two electrodes is high enough, the intervening gas can no longer function as a full insulator, and the current will cross the gap, resulting in an electric arc. This arc emits significant heat and produces a distinctive arc-shaped light. Arc welders harness this arc as the primary heat source for welding.

In direct current electrode positive (DCEP or reverse polarity), the electrode is connected to the positive terminal, and the base material to the negative terminal. However, some processes use direct current electrode negative (DCEN) or alternating current (AC), depending on the application and desired penetration. This configuration allows the arc to form between the two.

The arc welding process typically operates at output currents ranging from 5 to 1,000 A, with output voltages between 8 and 40 V. The temperature of the arc itself can reach an impressive 5,000-20,000°C, significantly surpassing the melting temperature of iron, which is approximately 1,500°C. As a result, the high-temperature arc melts the base materials (and in some cases, the electrode), causing them to fuse together during the welding process.

What Are the Advantages of Arc Welding?

Arc welding offers several advantages that make it a popular choice in various industries. Some key advantages are listed below:

- It can be used on a wide range of metals and alloys.

- The equipment is portable, so it gives operators great flexibility.

- It can produce high-quality welds with good mechanical strength.

- Arc welding can be performed in flat, horizontal, vertical, and overhead positions, offering flexibility for different job-site conditions.

- It’s suitable for outdoor applications where environmental conditions may not be ideal. The gas or flux shielding protects against atmospheric contamination.

What Are the Disadvantages of Arc Welding?

Arc welding also has some limitations and disadvantages that should be considered. The disadvantages of arc welding are listed below:

- Operators need skill and training to ensure proper execution.

- Welds can be challenging when working with thin materials. The high heat generated by the arc can cause distortion, warping, or burn-through of the base metal.

- Arc welding processes often produce slag or spatter during the welding process. This necessitates additional cleanup and post-weld finishing.

- Compared to some other welding methods, such as laser welding, arc welding generally takes longer. The deposition rate of filler material is slower, and multiple passes may be required to achieve complete joint penetration for thicker workpieces.

- The process generates intense heat, bright light, and potentially harmful fumes, which pose safety hazards to welders.

- Maintaining a stable arc typically requires a reliable and consistent power supply.

What Is Laser Welding?

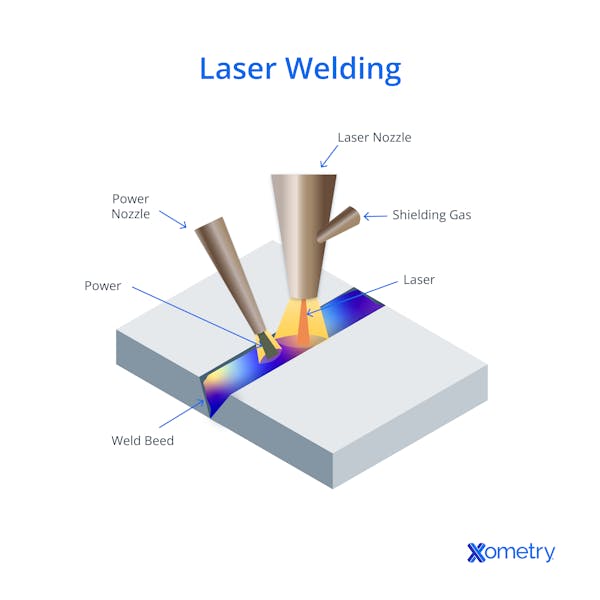

Laser welding, also known as laser beam welding or LBW, uses a focused beam of high-intensity laser light to join two or more metal components together. The laser beam generates intense heat that melts the material in the vicinity of the weld joint, creating a molten pool. As the laser beam moves away, the molten material solidifies, forming a strong weld bond.

The laser used in welding is generated by a laser source (such as fiber, disk, or CO₂ lasers), which produces a coherent beam of light through stimulated emission. The laser beam is then directed to the weld joint using mirrors or fiber optics.

There are two main laser welding modes: conduction mode and keyhole mode welding. These differ primarily in the laser's power density and penetration depth.

How Important Is Laser Welding in Manufacturing?

Laser welding holds great importance in the field of manufacturing because it has many advantages over traditional welding methods. Its precise control over heat input allows for highly accurate welds, making it invaluable for electronics, medical devices, and aerospace. Additionally, laser welding enables high welding speeds, enhancing productivity and efficiency in automated manufacturing processes. Laser welding can also join dissimilar metals and, with special configurations, certain plastics and ceramics.

What Is Laser Welding Used For?

Laser welding is used in a wide range of applications across various industries, including automotive, aerospace, electronics, medical, and jewelry. Some common applications include:

- Joining automotive components such as body panels, chassis parts, exhaust systems, and engine components.

- Assembling delicate electronics such as sensors, microcircuits, and battery tabs with minimal thermal distortion.

- Precise and clean welding of small and intricate parts of medical devices.

- Repairing jewelry, creating complex designs, and joining small components.

For more information, see our guide on What Laser Welding is Used For.

How Does Laser Welding Work?

Laser welding works by directing a high-power laser beam onto the joint between two metal components. The intense energy melts the material at the interface, and upon cooling, the components fuse into a solid weld.

Laser welding is often automated using robotic systems, which deliver precise and consistent energy at high speeds. The laser is typically delivered through flexible fiber-optic cables, enabling narrow, high-aspect-ratio welds with minimal distortion. Handheld laser welding systems offer portability but require strict safety measures due to the risk of eye damage, burns, and high-intensity light exposure.

What Are the Advantages of Laser Welding?

Laser welding offers several advantages compared to traditional welding methods. Here are some key advantages of laser welding:

- Laser welding allows for precise heat input control, resulting in minimal distortion and highly accurate weld placement.

- The concentrated energy of the laser beam allows for rapid heating and cooling, reducing overall cycle times and increasing efficiency.

- It is applicable to various thicknesses, from thin foils to thicker plates, and can create both narrow and deep welds.

- The localized heating generated by a laser results in a small heat-affected zone. This reduces the risk of thermal distortion, minimizes damage to adjacent materials, and preserves the mechanical properties of the base material.

- It’s a non-contact process, and there is no direct physical contact between the welding head and the workpiece during energy delivery.

- Laser welds require no electrode and, depending on the application, may not require filler materials. This can reduce consumable costs and simplify logistics.

- It is well-suited for automation and integration into production lines. Laser welders can be easily integrated into robotic systems.

- Lasers create aesthetically pleasing welds with minimal surface imperfections.

What Are the Disadvantages of Laser Welding?

While laser welding offers several advantages, there are also some disadvantages of laser welding to consider:

- Laser welding equipment can be expensive to purchase and maintain compared to traditional welding equipment.

- High-power lasers inherently pose safety hazards.

- The process can be sensitive to workpiece surface conditions. Contaminants, coatings, or surface irregularities can affect beam absorption and weld quality.

- Laser welding is typically more effective for thin to medium-thickness materials (generally up to about 10–12 mm without filler; deeper welds may require multiple passes or hybrid processes).

- Some traditional laser types, such as CO₂ lasers, have energy conversion efficiencies under 10%. However, modern fiber lasers typically achieve efficiencies of 25–40%.

- Laser welding requires skilled operators with knowledge and experience in laser parameters, optics, and process control.

How Do Laser Welding and Arc Welding Differ in Heat Source?

Laser welders use a concentrated laser beam as the heat source, while arc welding creates heat using an electric arc.

In laser welding, a high-intensity laser beam delivers concentrated optical energy to the joint, where it is absorbed by the material, causing localized melting and fusion.

In arc welding, an electric arc is generated between an electrode and the workpiece. The arc ionizes the surrounding gas, creating a plasma that produces intense heat, which melts the base metal and, if applicable, the electrode (except in GTAW, which uses a non-consumable electrode).

How Do Laser Welding and Arc Welding Differ in Equipment?

Laser welding and arc welding are two distinct welding processes that differ significantly in terms of equipment. Laser welding requires a laser source (e.g., fiber, CO₂, or Nd:YAG), beam delivery optics or fiber, a high-precision workpiece positioning system, shielding gas supply, and an advanced control system. Arc welding typically involves a power supply, electrode holder or wire feeder, ground clamp, shielding gas supply (if applicable), and a simpler control interface.

How Do Arc and Laser Welding Compare in Speed and Power?

Arc welding processes, such as SMAW or GMAW, generally have lower welding speeds and deposition rates compared to laser welding, especially in automated or precision applications. The deposition rate in arc welding varies with electrode type, current, polarity, and travel speed, but typically results in slower throughput than laser systems. On the other hand, laser welding is renowned for its speed. The concentrated laser beam with a high power density heats the material rapidly, resulting in fast travel speeds and efficient welding. Hybrid laser-arc welding offers higher travel speeds and deeper penetration than conventional arc welding, especially in thick-section welding.

Arc welding uses electrical power to maintain an arc between an electrode and the workpiece, generating heat for melting filler and base materials. The current in arc welding typically ranges from 20 A to over 600 A, depending on the process and material thickness. Arc welding parameters vary with electrode type, base metal properties, joint design, and the required penetration depth. In contrast, laser welding relies on a high-power laser beam as the heat source. Laser welding power is measured in watts (W) and can range from 50 W in low-power systems to over 10 kW in industrial applications. The concentrated and powerful laser beam allows for efficient and precise heating of the material, leading to rapid melting and fusion of the joint.

Common FAQs About Arc Welding vs. Laser Welding

Is Laser Welding More Expensive Compared to Arc Welding?

It depends. Laser welding systems have significantly higher upfront costs than traditional arc welding equipment, often by an order of magnitude. However, laser welding is considered a faster welding process. This makes it more cost-effective in the long run. Laser welds are often cleaner and more precise, reducing the need for post-weld grinding or finishing, which lowers labor and rework costs. Laser welding often does not require consumables like filler wire or electrodes, which simplifies logistics and reduces operating costs over time.

Which Is Easier to Use, Arc or Laser Welding?

In both cases, ease of use depends on several factors, including the operator's skill level, the welding application, and the specific equipment being used. However, in general, arc welding is considered to be more accessible and easier for beginners or less-experienced welders to learn. Arc welding processes, such as shielded metal arc welding (SMAW) or gas metal arc welding (GMAW), are commonly taught in welding training programs and are widely used in many industries.

Laser welding typically demands more specialized training due to the need to understand laser parameters such as power, focus, and speed, along with optics handling and beam safety protocols. Much of the equipment is complex, demanding precise control of the beam and other parameters, so it often requires more expertise and experience. Additionally, the use of lasers comes with unique safety considerations that other welding methods don’t have. Laser welders, however, are often integrated into automated systems, so with the correct laser settings, they can be more efficient.

Is Laser Welding as Strong as Arc Welding?

Yes, laser welding can match or exceed arc weld strength, particularly in applications requiring precision or involving thin sections where heat input must be minimized. Not only that, but lasers typically do the job three to ten times faster. High-power laser systems can weld sections up to ~20 mm thick in a single pass, though this depends on the material and beam quality. This reduces thermal distortion and maintains joint integrity. Laser processes are also better at joining thin metal pieces without causing damage or distortion; arc welding usually leaves behind significant distortion.

However, it is important to note that the strength of a weld is not solely determined by the welding process itself. Proper joint preparation, material selection, parameter optimization, and post-weld heat treatment (if required) all play crucial roles in achieving strong welds regardless of the heating method.

Can Arc and Laser Welding Be Used Together?

Yes, laser welding and arc welding can be combined. This is known as laser-arc hybrid welding. It is an emerging technique that combines the use of an electric arc and a laser beam. It involves the simultaneous application of a laser beam and an electric arc in the same weld pool, combining the depth of laser welding with the gap-bridging ability of arc welding. The deep penetration capabilities of laser welding are combined with the weld cap profile achieved by arc welding processes. Laser-hybrid welding uses shielding gases and sometimes filler wire to stabilize the arc and improve weld quality, especially for thicker or less precise joints.

Summary

This article presented arc welding vs. laser welding, explained what it is, and discussed its various applications. To learn more about the differences between arc and laser welding, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.